What Is Rotary Broaching

How Does Rotary Broaching Work

What Forms Can Be Broached

What Material Can Be Broached

Can You Align The Broach

Are There Any Limitations

Speeds And Feeds

Custom Forms And Sizes

How To Choose The Correct Tool Holder

Different Types Of Tool Material

WHAT IS ROTARY BROACHING

Rotary broaching, sometimes referred to as wobble broaching, has been around for over 100 years and is an extremely fast and accurate method of machining internal and external forms like hexagons, squares and splines.

Unlike conventional push and pull broaches, rotary broaching allows you to produce extremely accurate polygon forms in blind or thru-holes on any lathe, mill or machining center without the need for a secondary operation. This method of machining precision forms has become increasingly popular in the medical and aerospace fastener industries.

This is a low heat operation so you will not run the risk of damaging your parts during the broaching process, which is another reason why the aerospace industry has moved towards the rotary broaching application as opposed to secondary wire EDM operations.

The benefits of rotary broaching are numerous:

- Extremely Quick and Accurate

- No Secondary Operations Required

- Adjustment-Free for Minimal Set-Up Time

- Relatively Inexpensive Tooling

- Works on Any Lathe, Mill or VMC

- Great Finish Quality

- Reduces Machining Time = Greater Profits

HOW DOES ROTARY BROACHING WORK

The entire process is as simple as drilling a hole! There are only two items required:

- Polygon Solutions’ Rotary Broach Tool Holder

- Rotary Broach Tool (Hex, Square, Torx, Serration, etc)

The rotary broaching operation can be performed in any CNC or Manual lathe, mill, screw machine, VMC or turning center.

PREPPING THE PART

There are a few required steps necessary to successfully broach internal forms.

- First, you will need to pre-drill a pilot hole. The pilot hole must be slightly larger than the minor diameter of the form and slightly deeper than the depth you are broaching the form. If you are broaching a blind hole please read: Blind Hole Broaching

- Second, you will need to add a chamfer to the pilot hole. The chamfer must be slightly larger than the major diameter of the form.

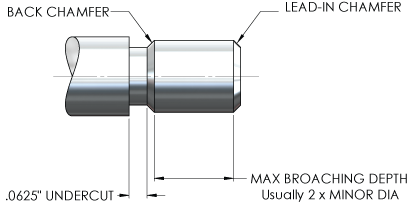

For the external broaching operation, you will need to:

- Turn the bar slightly below the major diameter of the form

- Add a lead-in chamfer and at the back of the area to be broached; and

- Add a .0625” undercut at the end of the form

HOW THE PROCESS WORKS

The Rotary Broach Tool Holder is what allows this process to work. The holder is offset 1 degree from the centerline of the shank allowing the broach to enter the part at an angle, only cutting one portion of the form at a time. The broach is feed into the part and the full form is cut in one pass. The rotary broach bit is designed with a back taper to prevent it from crashing into your workpiece while feeding the broach into the pilot hole.

As the broach cuts, the material curls in separate chips. These chips can be left in the bottom of the hole or removed using the same pilot hole drill. For external forms, it is recommended to provide a relief undercut at the end of the form so the chips fall off when the broach reaches the desired depth.

Illustration of Rotary Broaching on a Lathe

Illustration of Rotary Broaching on a Mill

WHAT FORMS CAN BE ROTARY BROACHED

Polygon Solutions offer the largest selection of forms that can be rotary broached. Although there are some limitations, most forms under 2” in diameter can be successfully broached using our tools.

Polygon offers standard sizes and well as custom sizes made to your specifications. Some common forms are hexagon, square, rectangular, Torx-style, serration, involute splines, keyways, single and double D, J500, Rosan, double square and 12-point (double hex).

If you have a print you would like Polygon Solutions to quote please email or fax it to us.

WHAT MATERIAL CAN BE ROTARY BROACHED

Materials like aluminum, brass and mild steels are ideal. However, because of the advancements of powdered metal steels like PM M-4 and PM T-15, rotary broaching has proven successful in materials such as titanium, 300 and 400 series stainless steel and Inconel.

Other materials that can be broached include: 4140, 416, 17-4, 1144, nickel, bronze, acrylic, copper, cast iron and many more.

Coatings such as TiN, TiCN, TiAlN and Alcrona Pro can also be beneficial for certain materials. Alcrona Pro is the preferred coating for rotary broaching applications.

If you have any questions regarding the steel you are machining please call us at 239-628-4800 and we will further assist you.

ALIGNMENT OF BROACH

Polygon Solutions has an innovative alignment tool that adapts to our tool holder which makes the alignment of the form very easy to achieve. Polygon’s alignment brake allows you to orientate or time the broach to align with another feature of your part.

This alignment tool also allows you to break the normal boundaries and limitations! For example, if you need to broach a form to a flat bottom hole where you cannot pre-drill deeper than you need to broach, this alignment tool allows you to broach in sections. That is, you can broach half way down, come out and remove the chips with the pre-dill and then return in the same hole holding the same orientation and finish the form to a flat bottom.

This alignment tools can also be used to align multiple passes. The biggest limitation is tooth height of the form. Polygon Solutions has now solved this issue by making a roughing and finishing broach to achieve a larger tooth on a serration or involute spline.

Another way this alignment brake can be used is when your form requires being pre-milled. If you are broaching a square form and you simple cannot pre-drill your pilot hole oversized because the customer needs completely flat sides then you can pre-mill out the square and then finish the form using our rotary broaching tools.

Here is a video showing how the alignment brake tool works:

LIMITATIONS OF ROTARY BROACHING

Although rotary broaching is an amazing way to produce internal and external forms it does have some limitations. However, Polygon Solutions has found a way to break through most of those limitations. The biggest limitation is depth. Usually the max depth is 1.75”. Second is the major diameter which should not exceed 2”.

TYPICAL SPEEDS AND FEEDS

Speeds and feeds vary depending upon many factors such as form, size, material, pre-drill diameter, and others. Most applications will fall somewhere between 500-700 RPM at a feed rate of .001” to .003” inches per revolution (IPR).

RECOMMENDED TIPS

It is good practice to engage the part with the spindle turning at 50-100 RPM at a feed rate of .001” to .002” IPR until you reach a depth of about .020” or when you clear the chamfer area. After that point, you can speed up your RPM and feed rate accordingly. This will prevent the broach from skipping around on the face of the chamfer which can cause unsightly witness marks from the tool entering the part. This process will also reduce the risk of chipping or fracturing the rotary broach which can diminished tool life.

*Never rapid out of the part, also feed out at a rate of .010” to .020” IPR.

CUSTOM FORMS AND SIZES

Polygon Solutions can custom make a rotary broach per your print or specifications. Custom size hex or square forms can typically be shipped same or next day. Custom forms like serrations or involutes can typically be shipped within 10 days.

ROTARY BROACH TOOL HOLDERS

Polygon Solutions offers 4 types of rotary broach tool holders. You should choose the tool holder that fits your range of expected broach sizes. For example, if you are broaching mainly smaller forms less than ¼” then the GT Series 8mm tool holder would be ideal for you. If you expect to broach forms larger than ½” than you will want Polygon’s Heavy Duty HT Series holder.

- Micro Tool Holder

- Swiss-type tool holder for swiss machines

- Ideal for smaller forms: .030” to .250”

- GT 8mm Series Tool Holder

- Polygon’s premium tool holder for 8mm shank broaches

- Ideal for smaller forms: .050” to .315”

- GT ½” Series Tool Holder

- Polygon’s premium tool holder for ½” shank broaches

- Ideal for medium forms: .081” to .630”

- HT Heavy Duty Series Tool Holder

- Polygon’s heavy-duty tool holder for ¾” shank broaches

- Ideal for larger forms: .500” to 2.50”

When ordering, make sure to specify the correct broach shank size to match your holder.

Use the table below to determine what shank size to order.

| Tool Holder | Broach Shank Diameter | Broach Shank Overall Length | Broach Size |

| Micro Tool Holder | 8mm | 28mm | Micro Broaches |

| GT 8mm Tool Holder | 8mm | 1.25” | 8mm Broaches |

| GT 1/2” Series Tool Holder | .500” | 1.75” | 1/2″ Broaches |

| Heavy Duty Tool Holder | .750” | 2.75” | 3/4″ Broaches |

CHOOSING THE CORRECT TOOL MATERIAL

Choosing the correct tool steel is crucial to the success of your rotary broaching operation. Polygon Solutions offers the following tool steels:

- M-2

- M-42

- PM M-4

- PM T-15

M-2 High Speed Steel is ideal for aluminum, brass, and other mild steels.

M-42 is a High Speed Steel with 8% cobalt and is recommended for 4140 and for varies pecking and punching operations.

PM M-4 is a powdered metal with a superfine grain that provides high wear resistance and is recommended for stainless steel.

PM T-15 is also a powdered metal with a superfine grain and is recommended for harder and more exotic materials such as Inconel or titanium.

If you need a recommendation on which material would best suit your application please contact our technical staff at 239-628-4800 ext 701.