Square Rotary Broaches

Peter Bagwell

2015-03-17T07:51:07-04:00

Choose Square Broach Shank Size

1/2 Shank

View our large selection of .500 inch shank diameter square rotary broach sizes.

Size Range .081 to .750

1/2 in. Shank Diameter

Order Square Rotary Broach with 1/2 in. shank diameter x 1.75 inch length.

View Sizes8mm Shank

View our large selection of 8mm shank diameter square rotary broach sizes.

Size Range .050 to .398

8mm Rotary Broaches

Order Square Rotary Broach with 8mm shank diameter x 1.25 inch length.

View SizesMicro Broaches

8mm shank diameter x 28mm overall length square micro rotary broach sizes.

Size Range .050 to .240

8mm x 28mm

Order Square Rotary Broach with 8mm shank diameter x 28mm length.

View Sizes

Do you need to make a precision square form in the end of a metal shaft or fastener?

Of the many ways to accomplish such a task, rotary broaching is no doubt the most popular, most efficient and most cost effective. Best of all, square rotary broaching tools work on almost all turning machines.

Of the many ways to accomplish such a task, rotary broaching is no doubt the most popular, most efficient and most cost effective. Best of all, square rotary broaching tools work on almost all turning machines.

Perhaps you’ve heard the riddle “It’s like trying to fit a square peg into a round hole”. This is interesting because a square shape can easily be made on the outside of a part, and a hole can be drilled on the inside of a part, however the two are not compatible. With rotary broaching however, squares holes are commonly made for custom sockets, shaft extensions and hardware components.

Using the square broach is not difficult, but a few key points should be kept in mind. Rotary broaching does require the use of a chamfer. The chamfer helps the broach to stay on center, and is also the point where the chip begins to curl up at the face of the broach.

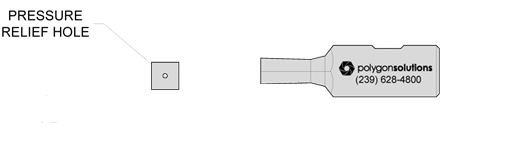

An oversize pilot hole is also an important key for rotary broaching. For squares, we recommend a minimum 10% oversize pilot hole, which will leave a small radius in the middle of the flat. This small amount of material removal is needed to create separate chips and reduce pressure. Pilot hole diameters closer to the flat-to-flat dimension of the broach can be used, but may affect tool life.

Finally, there must be room for the chips to accumulate in the bottom of the hole. If the pilot hole is a through hole, then generally this is not a concern. However, if it is a blind hole, consideration must be given to provide clearance for chip accumulation inside the hole. Drilling the pilot hole 50% deeper than the broaching depth is a rule of thumb for determining final pilot hole depth.

Polygon Solutions is pleased to provide a wide variety of standard inch and metric square broach sizes suitable for rotary broaching. Most broaches are available for immediate delivery from our Fort Myers, FL facility. Polygon also offers fast delivery on custom and special order square broaches.

Square Rotary Broach Custom Options

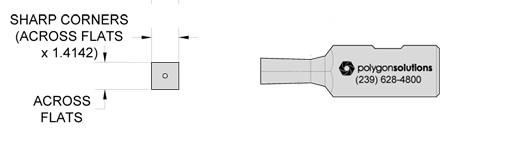

Our Square Rotary Broaches can be ordered in custom dimensions. Can’t find the size you’re looking for? Polygon Solutions provides fast delivery on custom ½” or 8mm shank square rotary broaches. Simply specify the desired across flat dimension when ordering. Polygon’s manufacturing tolerance is +0/-.0005”. For example, a custom square broach with 0.1234” across flat dimension is part number S01234B.

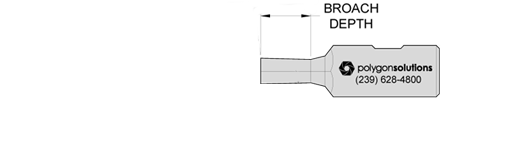

If you need a square rotary broach to cut deeper than our standard dimensions, perhaps to clear a counter-bore, you can request a custom cut length. Custom cut lengths may be limited by the back-taper on the side of the square broach, or manufacturing limitations. Please call (239) 628-4800 for more information. Rotary broaching more than 1-2x the across flat dimension may not be successful. Broaches may also be weakened because of a deeper cut length.

The standard rake angle (also called the dish angle) is critical to help the chip curl while rotary broaching. However, the rake angle can be modified to suit specific materials. For example, some softer materials may require a steeper angle. Broaching tougher materials may be improved with less, or no rake angle. Please call (239) 628-4800 for more information.

Single vent holes are standard with square rotary broach forms larger than .079″ and allow air and/or fluid to pass though the hex broach and reduce any hydraulic pressure that may occur when broaching a blind hole. Polygon’s rotary broach tool holder is also designed with this feature. However, an additional cross vent hole can be added for holders without the pressure relief system.

All of Polygon Solution’s square rotary broaches are manufactured with a +0/-.0005” tolerance. However, square broaches can be manufactured to a tighter +0/-.0004” tolerance. If you want to use the broach as a gauge, the square broach can also be manufactured without a back-taper. For more information, see

Rotary Broach Gauges.

If you part allows for a corner radius, we can add a spun ground diameter to the square broach to remove the sharp corners. The spun ground diameter is useful for reducing the chip size and pressure required for long tool life and successful rotary broaching operations.

![]() Of the many ways to accomplish such a task, rotary broaching is no doubt the most popular, most efficient and most cost effective. Best of all, square rotary broaching tools work on almost all turning machines.

Of the many ways to accomplish such a task, rotary broaching is no doubt the most popular, most efficient and most cost effective. Best of all, square rotary broaching tools work on almost all turning machines.