Polygon Solutions is one of the leading companies manufacturing Rotary Broach Tools here in the U.S.A. Our continuous effort to research and implement new technologies in the rotary broach process separates us from the others.

It is well known that rotary broaching caused pressure while a workpiece is being broach which could cause a multitude of problems. To eliminate this problem Polygon Solutions developed a rotary broach tool holder that implements a pressure relief hole to allow air and fluid to escape. In order for this technology to work properly the rotary broach tool must also have a vent hole through it so we designed our rotary broach cutting tools to include a pressure relief vent hole at no extra charge to our customers. Anyone using a Polygon Solutions’ rotary broach tools and holder will experience the benefits of having a pressure relief vent hole that relieves the pressure caused by this process possibly adding life to the tool, tool holder and the machine being used as well as mitigating any problems that may arise during the broaching process.

Polygon Solutions offers a large variety of rotary broach tools in stock and ready for delivery. Most orders are shipped within hours of being placed so as to ensure that you receive your products immediately. Our rotary broaches are made from M2 High Speed Steel however they may be produced with PM M-4, M-42 or PM T-15. Polygon Solutions is one of select companies that offer M-42. Our research shows that in some cases M-42 can outlast and out perform PM T-15. If you have questions concerning which material is most suitable for your application please contact our technical support staff at 239-628-4800 ext. 703.

|

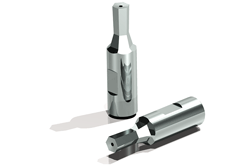

Our 8mm Shank Hexagon Rotary Broach Tools are available in standard or metric sizes and can be produced from M2, PM M-4, M-42 or PM T-15. To add longevity to the life of the cutting tool coatings such as Titanium Nitride, Titanium Carbo-Nitride or Titanium Aluminum Nitride can be applied. Pressure relief vent holes are standard on all of our rotary broach tools. |

|

Our 1/2″ Shank Hexagon Rotary Broach Tools are available in standard or metric sizes and can be produced from M2, PM M-4, M-42 or PM T-15. To add longevity to the life of the cutting tool coatings such as Titanium Nitride, Titanium Carbo-Nitride or Titanium Aluminum Nitride can be applied. Pressure relief vent holes are standard on all of our rotary broach tools. |

|

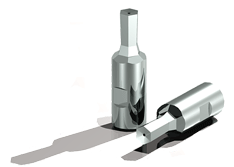

Our 8mm Shank Square Rotary Broach Tools are available in standard or metric sizes and can be produced from M2, PM M-4, M-42 or PM T-15. To add longevity to the life of the cutting tool coatings such as Titanium Nitride, Titanium Carbo-Nitride or Titanium Aluminum Nitride can be applied. Pressure relief vent holes are standard on all of our rotary broach tools. |

|

Our 1/2″ Shank Square Rotary Broach Tools are available in standard or metric sizes and can be produced from M2, PM M-4, M-42 or PM T-15. To add longevity to the life of the cutting tool coatings such as Titanium Nitride, Titanium Carbo-Nitride or Titanium Aluminum Nitride can be applied. Pressure relief vent holes are standard on all of our rotary broach tools. |

|

Our 8mm Shank Torx Style Rotary Broach Tools are available in T-10, T-15, T20 & T-25 sizes and can be produced from M2, PM M-4, M-42 or PM T-15. To add longevity to the life of the cutting tool coatings such as Titanium Nitride, Titanium Carbo-Nitride or Titanium Aluminum Nitride can be applied. Pressure relief vent holes are standard on all of our rotary broach tools. |

|

Our 1/2″ Shank Torx Style Rotary Broach Tools are available in T-10, T-15, T20 & T-25 sizes and can be produced from M2, PM M-4, M-42 or PM T-15. To add longevity to the life of the cutting tool coatings such as Titanium Nitride, Titanium Carbo-Nitride or Titanium Aluminum Nitride can be applied. Pressure relief vent holes are standard on all of our rotary broach tools. |