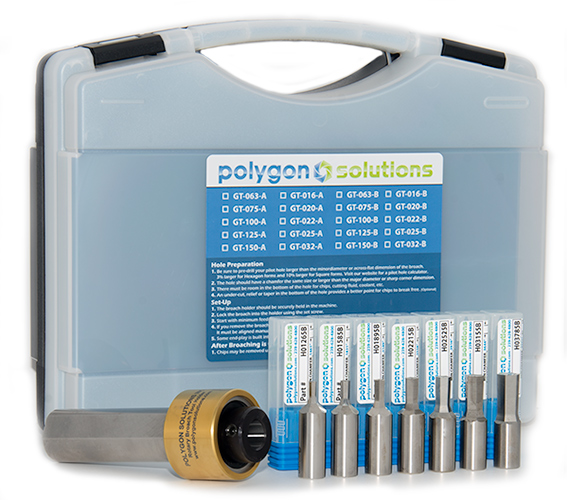

Polygon Solutions Inc. manufactures rotary broach tools used for making hexagon shaped holes in bone screws and other precision machined products. Rotary broaching requires two components, a broach holder and a rotary broach. The company’s latest product is an ‘all in one’ kit, improving productivity by featuring the holder and broaches needed to machine the most popular sizes.

Rotary broaching itself is a very old technique, originally patented one hundred years ago using a dedicated machine to make one hexagon or square hole at a time. During the 1950’s, rotary broach tools were adapted to fit screw machines, which were now making thousands of parts at a time. Polygons’ innovative broach holder, released in 2010, has modern features that make it more suitable for today’s highly flexible computer controlled (CNC) turning machines.

Polygon’s GT Series rotary broach holder uses the standard rotary broach sizes made popular since the screw machine era. The two sizes include .500” diameter by 1.75” length broaches, or 8mm diameter by 1.25” length broaches. Polygon is releasing two different kits to suit the preferences of customers who want to be able to continue to use the older style broaches.

The broach holder is not the only product with advanced technology. Each of the rotary broaches also includes pressure relief holes to allow fluid or air trapped in blind holes to escape through the center of the broach and out the side of the broach holder. Cutting fluids such as oil or coolant are often used when rotary broaching to improve surface finish and lubricity.

The rotary broach kit will include the holder, a case, instructions and multiple broaches to make the most common sizes specified for Allen wrenches or hex keys. Many customers have requested a discounted kit to save the time required to order all of the needed broaches one by one. The kit improves productivity and helps avoid the frustration of upgrading the broaching system with two or three broaches, only to have to pay for shipping again to get just one or two more sizes that were needed later.

Grease is not required for the rotary broach kit because the GT Series broach holder features sealed bearings, eliminating the need for messy grease guns in the work station. Supplementary spanner wrenches and tools for alignment are not required due to the time saving adjustment free features of the holder. The easy to use plug-and-play features are ideal for all machinists new to the rotary broaching technique.

Polygon’s rotary broach system kit is suitable for lathes, mills and CNC turning machines and works with many early versions of broaching tools. The kit includes broaches made from M-2 high speed steel, which is suitable for machining aluminum, brass and mild steel. Machining stainless steel or tough alloys may require broaches upgraded to different materials.

Fast delivery and online ordering make upgrading rotary broach tools easy. Price discounts for ordering multiple broaches together and a handy case to keep the tools organized also save time and money. To learn more, please visit https://www.polygonsolutions.com.