How Rotary Broaching Works | Extremely Fast & Accurate

Rotary Broaching is a precision method for producing internal polygon forms at an extremely fast rate. The entire operation can be completed within seconds and can produce forms to 0.0005″ accuracy or better saving your company time, money and resources.

Rotary Broaching is a precision method for producing internal polygon forms at an extremely fast rate. The entire operation can be completed within seconds and can produce forms to 0.0005″ accuracy or better saving your company time, money and resources.

The Basics of How Rotary Broaching Works

Rotary Broaching, also known as Wobble Broaching, is unlike the conventional broaching method. The conventional method has a sequence of polygon or other forms that increase in size and are pushed through a hole until the desired form size is achieved. Rotary Broaching can achieve this in one pass by cutting the full form, one corner at a time, often eliminating the need for a secondary operation. This works exceptionally well on Horizontal or Vertical Spindle Machines such as Lathes, Mills, etc. Rotary Broaching is a precision method for producing internal polygon forms at an extremely fast rate. The entire operation can be completed within seconds and can produce forms to 0.0005″ accuracy or better. This advanced engineering has caused Rotary Broaching to become increasingly popular; especially in the medical, automotive, aerospace and plumbing industries.

Rotary Broaching, also known as Wobble Broaching, is unlike the conventional broaching method. The conventional method has a sequence of polygon or other forms that increase in size and are pushed through a hole until the desired form size is achieved. Rotary Broaching can achieve this in one pass by cutting the full form, one corner at a time, often eliminating the need for a secondary operation. This works exceptionally well on Horizontal or Vertical Spindle Machines such as Lathes, Mills, etc. Rotary Broaching is a precision method for producing internal polygon forms at an extremely fast rate. The entire operation can be completed within seconds and can produce forms to 0.0005″ accuracy or better. This advanced engineering has caused Rotary Broaching to become increasingly popular; especially in the medical, automotive, aerospace and plumbing industries.

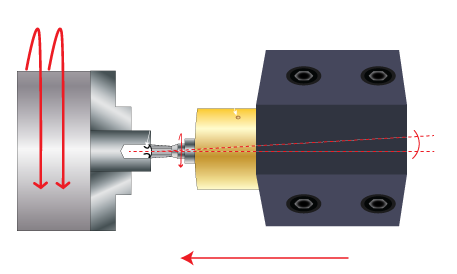

1) Rotary Broach Tool Holder

2) Rotary Broach

The principle that makes this process work is the 1° angle of the cutting tool to the centerline of the work piece. This causes the Rotary Broach to shear into the work piece, with a chisel or scalloping effect, as the broach is fed into the part to the depth required. The Rotary Broach Tool Holder has a live spindle that holds the broaching tool, allowing the spindle to spin freely within the Tool Holder. In a lathe, the spindle is driven by contact with the rotating work piece. Our Rotary Broach Tool Holders are adjustment-free so there is minimal setup required. The holders include such features as sealed bearings (which require no routine maintenance), and a pressure relief hole that allows air and fluid to freely escape.

With Rotary Broaching it is possible to broach such forms as Hexagon, Square, Torx, Serration, Keyway, Double Keyway, Double Square, Double D, Double Hex, Involute, Spline, Spur Gear, J500, Numbers, Letters and Other Polygon Forms.

Rotary Broaching is the most superior method used to get a polygon form into the end of a part without the need for a secondary operation.

Rotary Broaching F.A.Q.s

Polygon Solutions specializes in manufacturing standard and custom hexagon and square rotary broaching tools. Because we make these broaches daily, we offer very fast delivery of custom broaching tools. Hex and square broaches with special dimensions can be shipped the next day.

Polygon’s part numbers are also easy to customize. For example, a standard 1/4” hexagon rotary broach with 8mm shank has a finished dimension of .2525” +0/-.0005”. The part number is H02525A. If you need a .275” hexagon, simply change the part number to H02750A.

Custom sizes include various polygon shapes and other features. Although hexagons and squares are the most popular, Polygon Solutions also can make triangle, octagon, dodecagon and others. Polygon also offers fast delivery on special D and double D shapes.

Splines and serrations take a little longer, usually only one to two weeks for delivery. Some forms such as double hexagon and double squares can be delivered faster.

Many customers ask if the broaches cut oversize or undersize. However, rotary broaches are precision ground to very tight tolerances. The holes that are cut will be nearly the exact same size as the broach. For this reason, most broaches are made to the high side of tolerance, so that as they wear, they will stay within the tolerance as long as possible.

Some imagine that if the broach is slightly off-center from the hole, each corner will be cut slightly larger than the intended form. However, this is not the case. The rotary broach will typically follow the pilot hole. If the hole is too far off-center, the tooling might break.

Others believe, or may have experienced, the rotary broach may cut an undersized hole. This rare situation is usually one of two problems. The first problem has to do with broaching thin wall parts. The walls expand while broaching and then shrink back to form resulting in an undersized hole.

The second reason for an undersized hole has to do with too much pressure in the broaching operation. Because the broach is not driven by live tooling, and has a back taper, it is possible for excessive pressure to cause the broach to push back, and result in a slight twist in the form. This is usually found when the operator puts a gage into the hole and finds that it will not fit, and he thus assumes it has cut undersize.

In the rare instance a twist is developing in the form, multiple solutions are available to remove it. First, the pilot hole can opened or other changes made to reduce the pressure. Second, the machine spindle can be reversed half-way through the hole, causing the twist to reverse direction, usually solving the problem. Finally, a guide post or fixture can be set-up to keep the broach aligned while broaching.

Rotary broaching stainless steel is challenging and can be unsuccessful. Two changes can be made from a standard rotary broaching set-up to make many broaching jobs work in stainless steel. The first change is with the broach material, and the second change is with the speeds and feeds.

The best grade for broaching stainless steel of all types is PM M-4. This powdered metal has a super-fine grain size and carbide microstructure resulting in extremely versatile high speed steel which provides a unique combination of high wear resistance with high impact toughness. Polygon Solutions recommends PM M-4 for broaching stainless steel and improving tool life in general.

When broaching stainless steel, please also consider these recommendations to speed and feed modifications.

1. SLOW THE FEED RATE FROM STANDARD .001″-.002″ IPR TO .001 IPR

3. SLOW THE SPEED TO 50-100 RPM UNTIL ENGAGED .005-.010″ THEN RAMP UP TO 700-800 RPM

Rotary broaching is a very accurate method of producing precision polygon forms in a variety of metal work pieces. Broaches are precision ground to insure accuracy, and the rotary broach holder is designed to help machinists make repeatable accurate forms on nearly all turning machines.

Rotary broach forms manufactured by Polygon Solutions are made to a standard +0/-.0005 inch tolerance. Hexagon and square broach part numbers include the dimension at the high side of the tolerance. Part #H02525A for example has a hexagon form, manufactured to 0.2525” +0/-.0005”.

The rotary broach holder is also designed with a small amount of endplay to help the broach follow the pilot hole. Many machines are not exactly aligned, and it is not uncommon for the broach to be slightly off center for many machining operations. Polygon’s GT broach holder allows the broach to find its center in the chamfer, resulting in a very accurate broached hole.

Rotary broaches are made from durable high speed steel. Smaller broaches, such as a 1/8” hex broach, can make over 1,000 parts in aluminum and other soft metals. Larger forms, such as an 8mm square, may only last into the mid 100’s. Calculating tool life is very difficult due to the number of variables in the rotary broaching operation. Some upgrades can extend tool life, such as premium broach material, coatings, spun-ground diameter and pressure relief holes. However, controlling the following variables will give you a good start at improving the tool life of your rotary broaches:

Chamfer to the sharp corner or major diameter of the broach

Minimize broaching depth

Plenty of room for chips is required

An oversize pilot hole is key for reducing chip size and separating curling chips

Machine capability

No work hardening from the drill

Sharp drills are required for smooth pilot holes

Broach tool alignment or concentricity to the work piece